Case Study on Systel’s Industry 5.0 Solutions in Steel Plant

A Speciality Steel Manufacturing Plant in India was operating 3 Nos of Centrifugal Compressors with Total Capacity of 14700 CFM. Each of these Centrifugal Compressors were installed with Orifice Plate Differential Pressure Flow Sensor for Measuring the Compressor…

Case Study on Industry 5.0 Benefits in Textile Spinning Plant

A Textile Spinning Plant with an Installed Capacity of 1,00,000 Spindles in the Southern City of Tamil Nadu was Consuming Close to 1300 CFM from 2 of their Rotary Screw Compressors of Capacity 850 CFM and 450 CFM respectively. The Compressors came with…

Case Study on

Understanding Compressed Air Audits

Performing a Compressed Air Audits typically utilize Data Loggers to measure Power (KW), Pressure, flow, Dewpoint, Temperatures, etc., and are designed to provide a very detailed look at the Compressed Air Utilization within a Given System. Results of such audits can…

Importance of

Compressed Air Flow Measurement

Compressed Air Systems are very dynamic and hence if not monitored will lead to huge mismatch between the Supply and Demand. Unbalanced Systems will result in,

– Over compensation of system pressures will increase artificial demand & increase of problems

Case Study on

Dew Point Measurement Important

The Value which is displayed in the dryer is the chiller evaporative temperature (water cooled dryers). Chiller is a closed stainless steel tank, which is weather resistant. These chillers are used to Maximise heat transfer rate with minimum pressure drop. Hence This should not be confused with pressure…

Case Study on Project Implementation & Maintenance

Compressed air systems are essential for many industrial and manufacturing operations. It is crucial that these systems are properly installed and maintained to ensure that they operate at the highest possible level of efficiency.

Project management to elevate or automate…

WHY SHOULD YOU CONSIDER DIGITALIZATION OF

COMPRESSED AIR SYSTEMS?

Compressed Air Systems are very widely used in almost all manufacturing industries and are usually the Single Highest Source of Energy Consumption in a Plant. Through Out the Compressor’s Life Time More than 76 % of the Costs are spent towards its Energy with the Capital and Maintenance Cost only at 12 % Each.

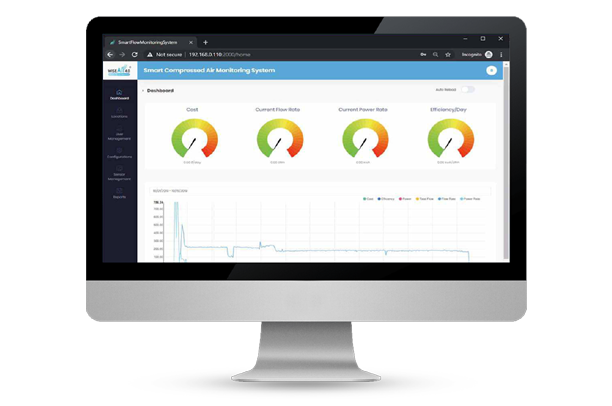

Solutions for intelligent compressed air management

A digitalized control system brings many advantages and enables far-reaching efficiency enhancing measures. In addition to reducing energy consumption and controlled self-optimization, a form of “predictive maintenance” can be implemented with the help of sensors. This is made possible by collecting data and evaluating them…

Case Study on Smart Monitoring Solutions for Compressed Air Systems

Compressed air systems are complex systems and often “grow over time”. With constant system monitoring using meaningful KPIs, operators, supervisors and management are kept informed and constructive energy management is possible. As up to 85% of total costs of a compressed air system are energy costs, investment in measurement…

Compressed Air Distribution Systems (Aluminum Piping Network)

The Compressor room header into which the air compressor discharges should be sized so that the air velocity within the header does not exceed 20 ft / sec, thus allowing for future expansion. Distribution header piping leaving the compressor room should be sized to allow an air velocity not to exceed 30 ft / sec to minimize pressure drop.

Regional Office

# 12 Sri Venkatalakshmi Nagar

Singanallur, Coimbatore – 641005

India